After moving out of the city to our new HQ in the Hunter Valley, the need for a Millfield gravel bike became immediately obvious. The local roads of the Hunter are typical of the rural and regional experience in Australia, where the local unsealed roads are often in better condition than the sealed roads.

Gravel bikes have become the solution for many cyclists, where both road riders and MTB riders can explore more of their local areas.

Our gravel project (like most of them) begins with a frame. In this case, it was a 60cm road frame built in the mid-80s by the legendary Australian framebuilder Kerry Hopkins. Built as a touring frame with pannier mounts and cantilever brakes, the frame spent many years in service of the original owner, a bike store employee in Newcastle NSW.

Unfortunately the frame was involved in a car accident in 2012, and the rear triangle was severely damaged. Under normal circumstances, this would consign the frame to the scrap bin, but it’s such a high-quality frame, the original owner gave it away. When we found it years later, we knew it had potential, and deserved a second chance.

The frame was brought back to bare metal with limestone blasting, which is much more gentle on the steel than glass or soda, and doesn’t leave small chips of paint behind. Aside from the crash damage, it was in good condition with no cracks or corrosion.

Finding the right framebuilder to fulfill our vision was easy – Sean at Killenbike. Sean has a talent for steel frame repairs and modifications, and we like his passion for gravel and bikepacking. We had a few discussions about specifications and what we planned to do with the frame, and we delivered the frame to Sean we knew that many of the decisions about the final product would be made by him.

The Build

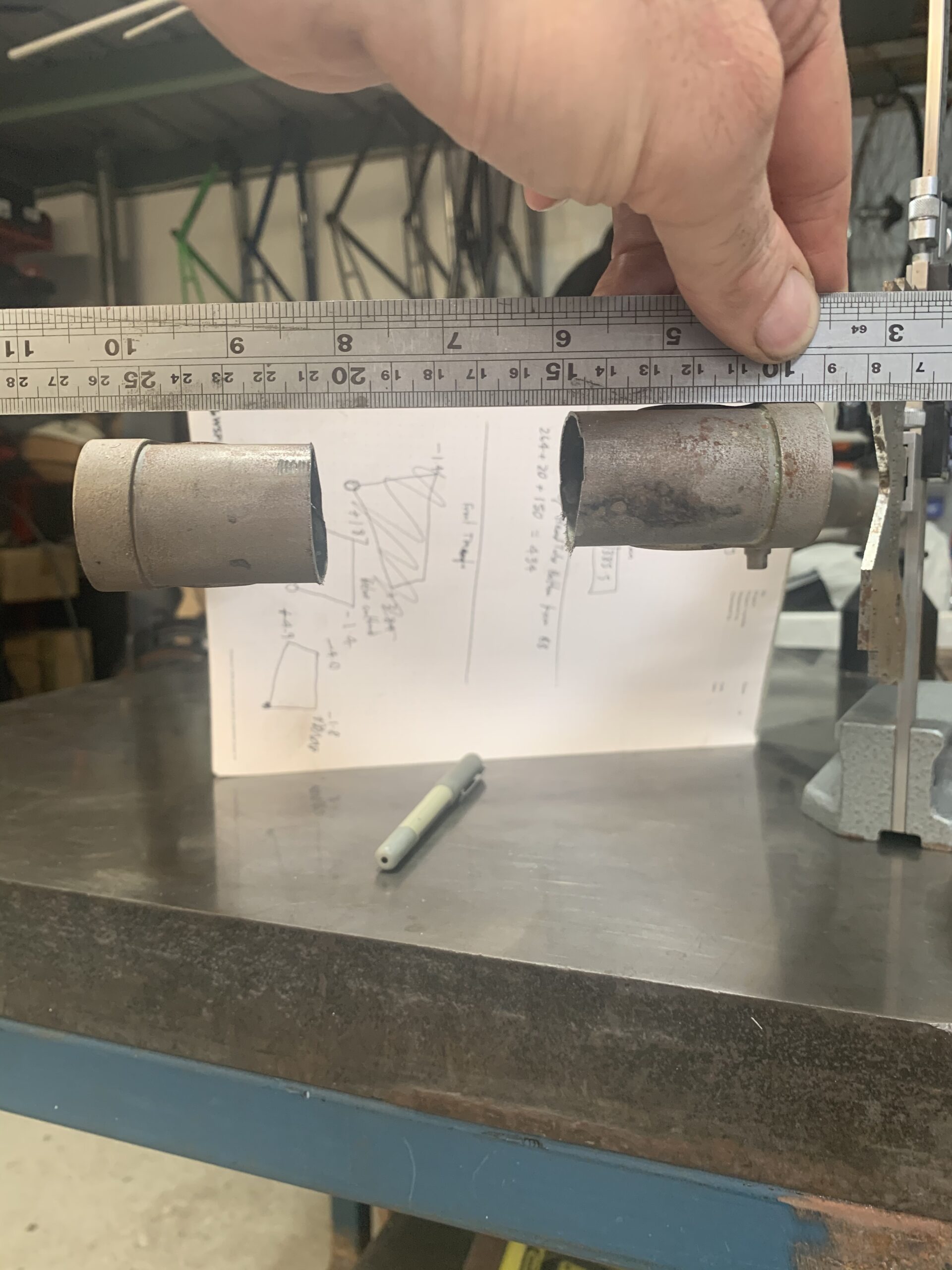

The bent rear triangle was removed and the headtube was machined off. The front triangle had some small alignment issues from the crash.

First up was a custom headtube, not only to update the frame geometry, but to allow the use of a modern tapered fork.

Sean manufactured a new tapered headtube with custom top and bottom rings that transitioned smoothly into the headset cups. The headtube was fillet brazed into the existing lugs, giving a lugged look.

Sean installed internal cabling ports into the downtube for shift and brake, using an internal crossover that keeps the cabling neat into the top entry – shift cable enters on the left and rear brake hose on the right.

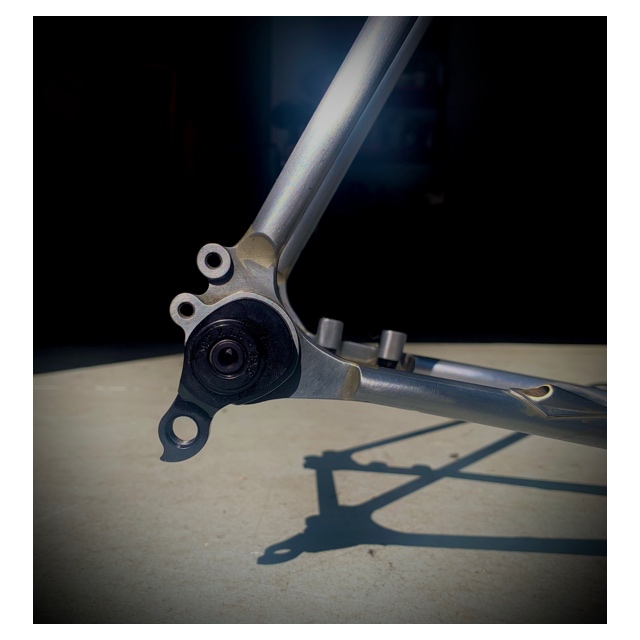

For strength Sean extended the lugs under the front of the chainstays around the new tube penetrations.

You can see in the photos that the cabling isn’t fully internal; there isn’t room in this 80s BB shell to run cabling inside. The cables come out the bottom of the downtube and go back into the chainstays. This is a great compromise and with the full routing of outer cable, the shift performance is reliable even in the muddiest of conditions.

The new asymmetric rear triangle was constructed for disc brake and 12 x 142mm through-axle wheels, using Paragon dropouts.

With the size of the rider on this XL frame, Sean felt that there would be too much flex in the BB.

This issue is amplified with the age of the front triangle, plus there’s a stack of new penetrations in the tubes from bidon mounts and internal cabling.

Given the bike will be used for gravel and bikepacking this issue can’t be ignored, both for strength and durability.

Sean solved the problem by adding a curved gusset in the lower triangle above the bottom bracket. This adds a classic look, increases strength and limits flex.

Note here the extension to the underside of the chain stay lug. This is superb craftsmanship and disappears when painted.

The Columbus gravel carbon forks are from Hillbrick, with a Columbus tapered headset. Note the way the headtube rings are customised to transition this headset.

These are superb forks, super strong with internal cabling for flat-mount brakes, 12mm through-axle hubs and ready for 700×40 tyres.

The hand-made ‘spear-tip’ seatstay caps are a work of art, made in a process that requires multiple mitering/brazing stages.

We followed Sean’s social media as the progress of the frame was completed. This is one of the custom bike build processes that can’t be rushed, and the final product was beyond our expectations.

The finished frame exceeded our expectations in every way, and we recommend Sean’s work to all of our customers.

A thouroughly modern frameset with such history…all of it from Australian builders. We couldn’t be happier.

Paint and decals

The completed frames went to Star Enamellers for painting in VW metallic blue and gunmetal grey. Peter added creative touches like the red highlights to dropouts and stem cap, plus a gunmetal panel on the inside of the forklegs. Three matching bidon cages were made in blue and red.

The custom red decals were designed and made right here in the Hunter by Sign Style and this bike celebrates the launch of the new Millfield headtube logo.

Groupset

As Sean was completing the frame rebirth, Campagnolo released the Ekar 13 speed gravel groupset. We wanted to be a part of the 13sp revolution, and thanks to some great work by the Campag importer Bikesportz, we got on the list for the first shipment of Ekar gruppos to arrive into Australia. This was in 2020, during COVID’s first lockdowns.

The Ekar uses a 1 x 13 setup with carbon cranks and a two-piece 9-42 rear cassette on the new N3W hub. The derailleur has a clutch to prevent chain slap in the worst trail conditions and the brake performance is amazing from the flat mount calipers and floating discs.

Our wheelset choice was a no-brainer: Campagnolo Shamal Ultra Disc. These alloy wheels are gravel-ready and incredibly strong…plus they look amazing with their innovative spoke pattern.

In the sunlight the bike is amazing to look at, and it’s superb to ride.

The initial running-in was completed on our local roads with Pirelli Cinturato 700×35 endurance tyres. It’s now updated to Pirelli Gravel Hard tyres in 700 x 35, running tubeless with Vittoria liners. It’s capable on both sealed and unsealed gravel roads, and we’ve even had it in the single track.

With Pro gravel bars and lights by Lezyne, this is an adventure bike for day or night. It has rack and pannier mounts for when we’re ready to do some bikepacking. We’ve added a Cane Creek eeSilk suspension seatpost for comfort on the long rides.

The bike now bears the name ‘KH-K’, for ‘Kerry Hopkins – Killen’. It’s an amazing bike and we love it more every time we ride it.